IADR Abstract Archives

Evaluation of Post Milling Microcrack Formation in Lithium Disilicate Block

Objectives: Lithium disilicate (LDS) glass ceramics is a material with high mechanical strength and aesthetics. Clinically, when the LDS glass ceramics is grinded by machine, microcracks are formed on the prosthesis. Generally, these microcracks are removed by polishing or glazing. However, if microcracks remain on the prosthesis, they could be an origin of fracture. The purpose of this study was to evaluate microcracks on surface of LDS glass ceramic block for CAD/CAM through polishing.

Methods: Materials used in this study are shown in Table 1. Samples of each material were fabricated by CEREC MC XL (Dentsply Sirona). EM was crystallized after griding. These samples were polished by following manufacturer’s instruction. Samples were immersed in 0.2% methylene blue solution to visualize microcracks on the surface by using digital microscope (VHX-7000, KEYENCE) (n=12). Number of microcracks were statistically analyzed by Tukey’s test. SEM (SU-70, HITACHI) observation was also carried out, and relative crystalline surface area (RCSA, n=5) was calculated by ImageJ (NIH).

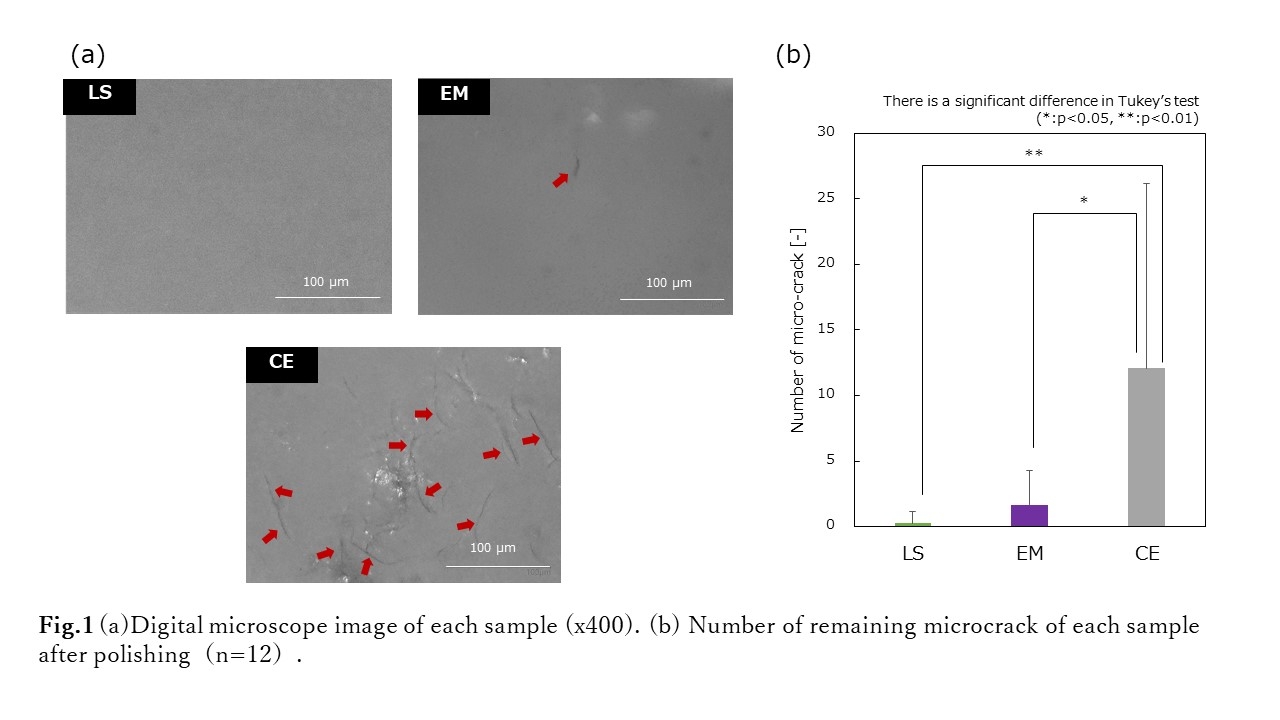

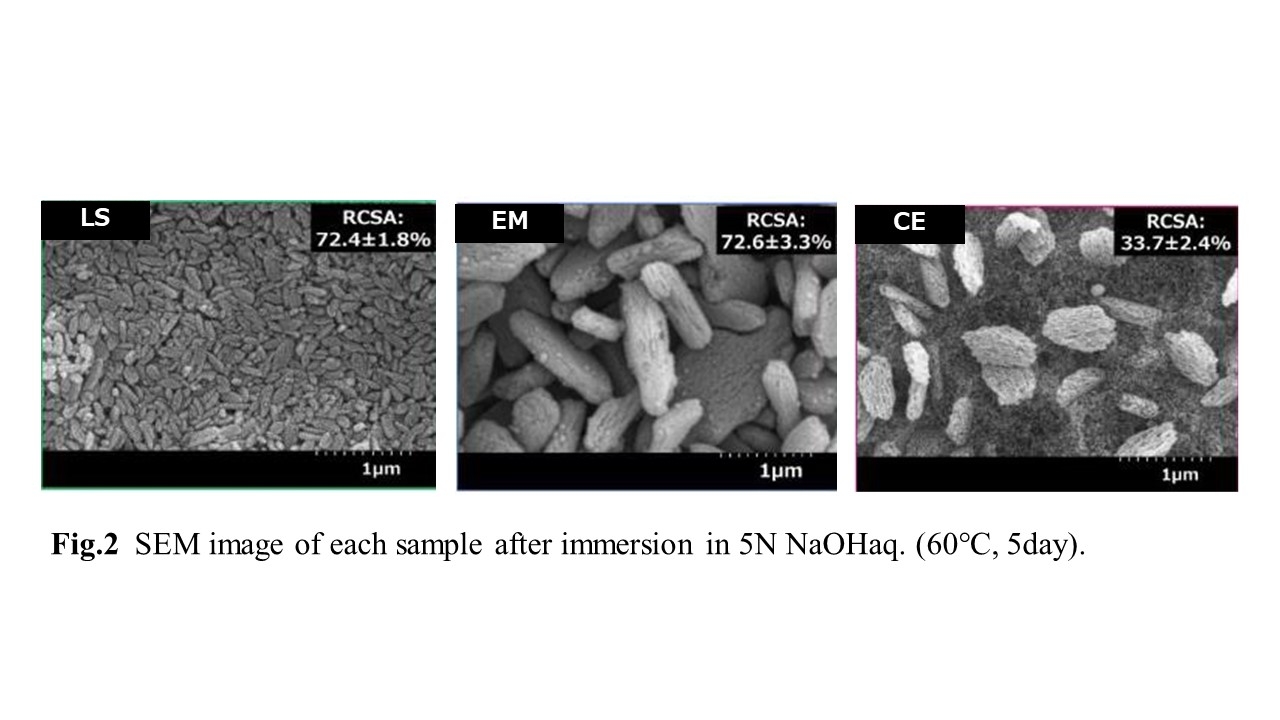

Results: Microcracks were observed on some sample surface after polishing (Fig.1(a)). The microcracks on the sample surface are shown by the arrows. Fig.1(b) shows the number of microcrack of each sample. Microcrack of LS and EM were significantly less than CE after polishing. As shown in Fig.2, LS and EM have higher value of RCSA compared to CE. LS showed less microcracks because it has high RCSA, densely dispersed small crystal grains and low glass ratio. In contrast, CE had many microcracks because it has low RCSA and high glass ratio. Microcracks of EM did not disappear after crystallization. It is considered that EM was deeply scratched due to the large crystals compared to LS.

Conclusions: It was suggested that LS has lower risk for microcracks to remain after polishing by having smaller crystal in higher density.

Methods: Materials used in this study are shown in Table 1. Samples of each material were fabricated by CEREC MC XL (Dentsply Sirona). EM was crystallized after griding. These samples were polished by following manufacturer’s instruction. Samples were immersed in 0.2% methylene blue solution to visualize microcracks on the surface by using digital microscope (VHX-7000, KEYENCE) (n=12). Number of microcracks were statistically analyzed by Tukey’s test. SEM (SU-70, HITACHI) observation was also carried out, and relative crystalline surface area (RCSA, n=5) was calculated by ImageJ (NIH).

Results: Microcracks were observed on some sample surface after polishing (Fig.1(a)). The microcracks on the sample surface are shown by the arrows. Fig.1(b) shows the number of microcrack of each sample. Microcrack of LS and EM were significantly less than CE after polishing. As shown in Fig.2, LS and EM have higher value of RCSA compared to CE. LS showed less microcracks because it has high RCSA, densely dispersed small crystal grains and low glass ratio. In contrast, CE had many microcracks because it has low RCSA and high glass ratio. Microcracks of EM did not disappear after crystallization. It is considered that EM was deeply scratched due to the large crystals compared to LS.

Conclusions: It was suggested that LS has lower risk for microcracks to remain after polishing by having smaller crystal in higher density.