IADR Abstract Archives

Physical Properties of Hybrid Ceramic CAD/CAM Blocks

Objectives: CAD/CAM restorations have been widely expanded in clinical cases globally. Moreover, the hybrid ceramic block, which consists of organic/inorganic components, is becoming more common for crown and inlay prosthesis because of its ease of fabrication and professional/patient satisfaction with aesthetics. We have further developed hybrid ceramics to improve the reliability and launched CERASMART 270 (GC, CS270) having high mechanical property. The aim of this study was to evaluate the physical properties of hybrid ceramic blocks.

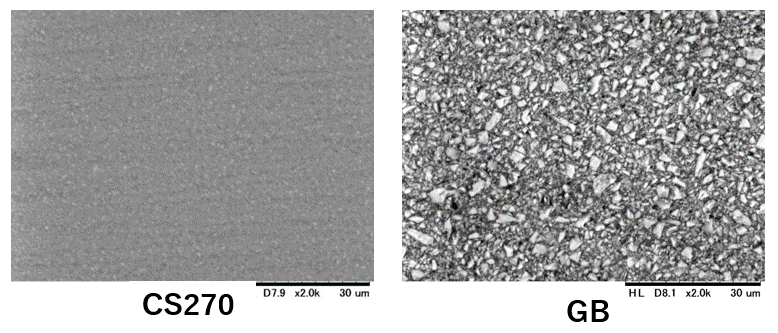

Methods: Commercially available hybrid ceramic blocks, CS270, Grandio blocs (VOCO, GB), MAZIC Duro (VERICOM, MD), Lava Ultimate (3M, LU), ENAMIC multiColor (VITA, EM) were tested. Mechanical properties were measured by 3-point flexural strength test. Test specimens were prepared in accordance with ISO6872 and flexural strength was measured using universal testing machine (AG-IS, SHIMADZU) with crosshead speed of 1 mm/min (n=10). In addition, the breaking energy was calculated from “Load-Strain Curve”. Results were statistically analyzed by Tukey-Kramer test (p<0.05). In order to analyze the microstructure, SEM analysis (TM3000, HITACHI) was performed.

Results: In the flexural strength test, CS270 and GB showed significantly higher results compared to other materials. Breaking energy of CS270 was significantly higher than GB. From the SEM image, it was confirmed that GB contained noticeable larger fillers compared to CS270. It is considered that high flexural strength of GB is from the use of micro-sized filler, resulting in lower toughness, while high flexural strength and toughness of CS270 are associated with the use of nano-filler. Therefore, it is expected that CS270 would have less fabrication failure, such as marginal chipping, and have higher load bearing capacity against occlusal forces.

Conclusions: In this study, CS270 showed higher flexural strength and breaking energy among the tested hybrid ceramic blocks which may lead to less chipping failure during fabrication and higher load bearing capacity against occlusal force.

Methods: Commercially available hybrid ceramic blocks, CS270, Grandio blocs (VOCO, GB), MAZIC Duro (VERICOM, MD), Lava Ultimate (3M, LU), ENAMIC multiColor (VITA, EM) were tested. Mechanical properties were measured by 3-point flexural strength test. Test specimens were prepared in accordance with ISO6872 and flexural strength was measured using universal testing machine (AG-IS, SHIMADZU) with crosshead speed of 1 mm/min (n=10). In addition, the breaking energy was calculated from “Load-Strain Curve”. Results were statistically analyzed by Tukey-Kramer test (p<0.05). In order to analyze the microstructure, SEM analysis (TM3000, HITACHI) was performed.

Results: In the flexural strength test, CS270 and GB showed significantly higher results compared to other materials. Breaking energy of CS270 was significantly higher than GB. From the SEM image, it was confirmed that GB contained noticeable larger fillers compared to CS270. It is considered that high flexural strength of GB is from the use of micro-sized filler, resulting in lower toughness, while high flexural strength and toughness of CS270 are associated with the use of nano-filler. Therefore, it is expected that CS270 would have less fabrication failure, such as marginal chipping, and have higher load bearing capacity against occlusal forces.

Conclusions: In this study, CS270 showed higher flexural strength and breaking energy among the tested hybrid ceramic blocks which may lead to less chipping failure during fabrication and higher load bearing capacity against occlusal force.